Thai Composites

Thai Composites Company Limited was established in 1999 to manufacture Reinforced Thermosetting Resin Conduit (RTRC) to substitute the import of conduit from Canada under the GRE trade mark.

The company has produced electrical conduit with full range capacity in the year 2000. But the sales and marketing are conducted by the affiliated company, GRE Composites Co., Ltd. At that time, Thai Composites Co., Ltd. (TCC) was considered as a leading manufacturer of epoxy fiberglass products in Thailand, especially conduit.

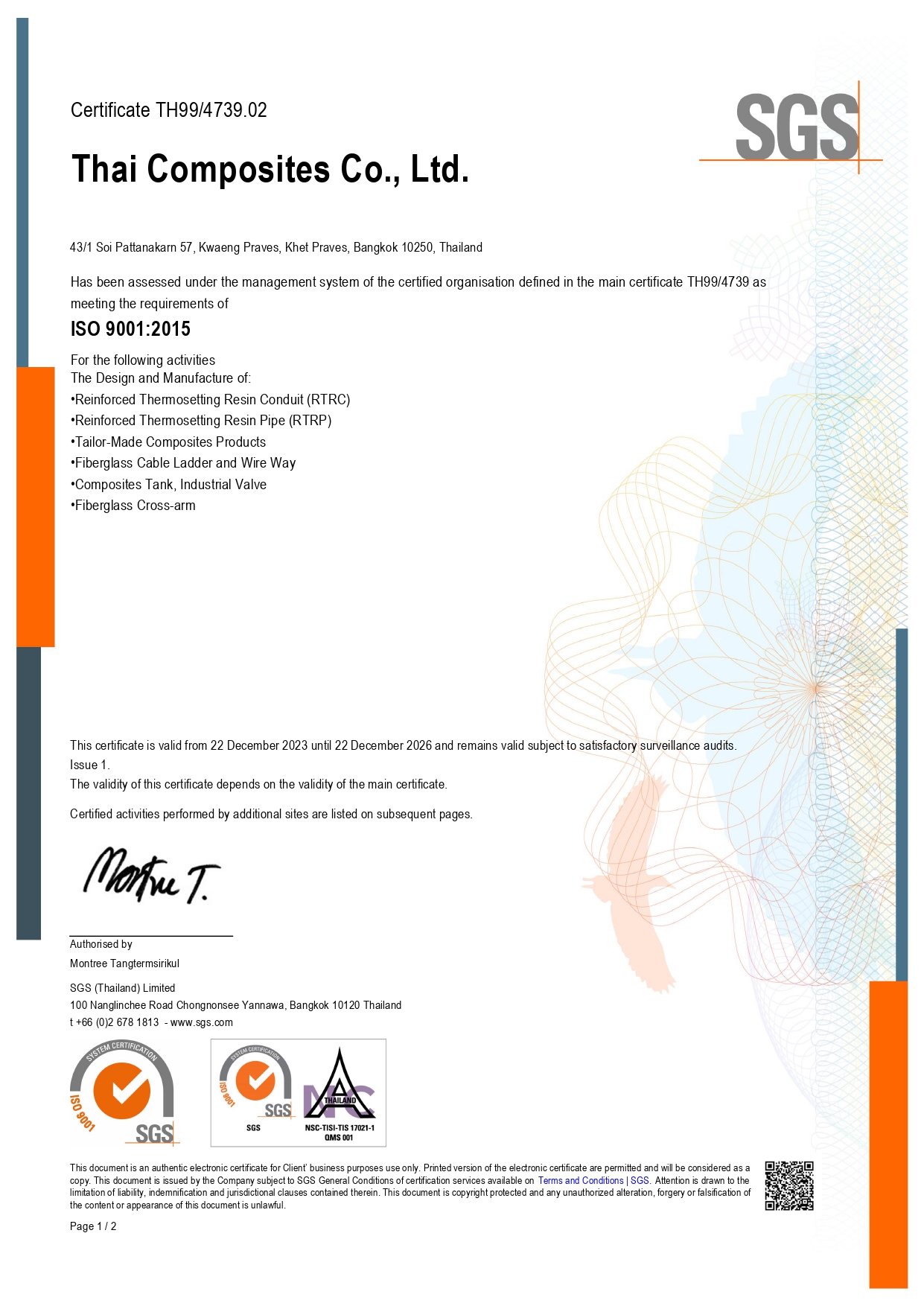

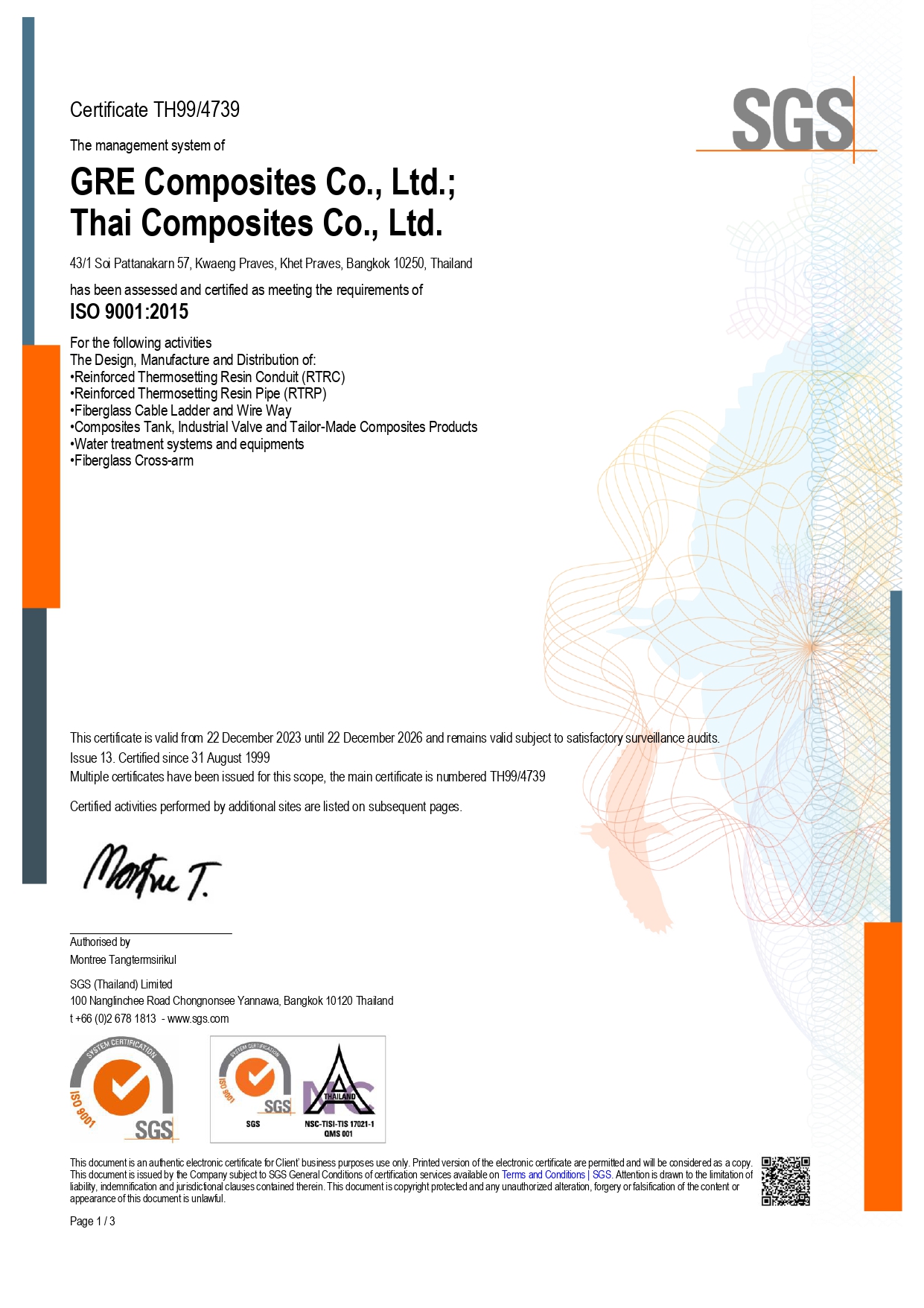

In the year 2000, TCC has implemented the ISO system to improve , control and develop the quality of work and production. In the year 2002, TCC has earned and received the ISO 9001:2000 certification. In the same year, we increased the production of FRP pipe to launch in the industrial systems, water supply systems, waste water treatment systems. All pipe has been designed and comply to TIS. 1483-2549, TIS. 1484-2540 and TIS. 1485-2540 respectively.

Both conduit and pipe are manufacturing under filament-wound process. Conduit is compliance

with NEMA TC 14 Part B while pipe has earned TIS standard and also produced, related to ASTM D 2996 and DIN 16965.

With the vision of the company founder, Thai Composites Company Limited has continuously developed and produced many composite products such as Cable tray, Storage tank, Pressure tank, Chemical tank, Scrubber tank, Water treatment system, Industrial valves and also Tailor-made products in order to serve the need and to give the solution to customers. This service is corresponded to the Mission of TCC.

To guarantee the highly recognized quality, our products are designed, manufactured and tested in compliance with the international standards such as NEMA, ASTM, UL, BSI, TIS and AWWA. The quality assurance program has been implemented throughout the process from raw material to final inspection before delivered products.

To achieve the quality plan, Vijai Composites Company Limited (VJ) was established in 2007. We have the engineers and scientists to handle the function of research, analyze and control quality of both material before production, physical and mechanical properties of finished products. To achieve our vision by being one of the leader in composite products in Asia, the research and development including quality analysis are the right answer to respond the customer’s satisfaction.

Thai Composites Company Limited and Vijai Composites Company Limited, located in Ban-Bueng District, Chonburi Province, with a total area of 32,000 square meters, consisting of 10,000 square meters of factory area and warehouse buildings with cranes.

TCC has invested in the production facilities such as computerized winding machine, the latest technology in curing system and the automated demolding machine. The facilities are controlled by our skilled and experienced workforce to ensure the consistent production of the high quality products.

VISION

We will be the company that supply and manufacture composite products to achieve customer’s satisfaction and create highest customer’s benefit.

MISSION

Electrical Works

• RTRC Conduit

• FRP Cable ladder/tray

• Custom made product i.e. Motor cover,

On load tap changer and FRP Cross arm

PRODUCTS AND SERVICE

Liquid-Gas Related Works

• FRP Pipe

• FRP Storage Tank

• FRP Scrubber Tank

• Composite Valves

• Water Treatment Plant

• Custom made product i.e. Reverse Osmosis Membrane

housing, Pressure vessel, FRP Grating and etc.

OUR COMMITMENT IS

“To produce and distribute high quality products which shall be acquired customer satisfaction is our commitment.”

COMPOSITE MATERIAL

Composite material is composing 2 or more materials together and become new material which has better properties than the original material alone. The properties of the new combination depends on the properties of the original materials, direction and distribution of reinforcing materials and the amount of material that is combined. For example, in the past clay is mixed with straw to make brick to build houses. Clay is hard but brittle when it is dry. But after mixed with straw, straw will act as a reinforcing material to clay and this mixture makes brick tougher and stronger.

PRODUCT STANDARDS

Our products are designed, manufactured and tested in accordance with international standards.

Manufacturing Standards

- RTRC Conduit: NEMA TC-14B, NFPA 70, NEC Electrical code and TIS 2518-2557.

- FRP Pipe: ASTM D 2996, ASTM D 3754, DIN 16965, TIS 1483-2549, TIS 1484-2540 and TIS 1485-2540.

- FRP Cable Tray: NEMA FG-1 and ASTM E84.

- FRP Storage Tank: ASTM D 3299, ASTM D 4097 and ASME RTP-1.

- Composite Vale: ANSI, DIN and JIS.

Test Standards

- ASTM (American Society for Testing and Material)

- AWWA (American Water Works Association)

- ASME (American Society for Mechanical Engineering)

- API (American Petroleum Institution)

- BSI (British Standard Institution)

- ANSI (American National Standard Institute)

- DIN (Deutches Institute fur Normung)

- JIS (Japan Industrial Standard)

- ISO (International Organization for Standardization)

Thailand Standards

- TISI (Thai Industrial Standard Institute)